Product Introduction: Alcohol residue is the residue used in the production of alcohol, with a quantity 0.65 times that of alcohol production. Alcohol lees contain varying degrees of protein and other useful elements, and their protein content is high (corn lees). Dried products can reach 28% to 30%, which can be used as high-quality feed and has a considerable market price; Cassava lees with low protein content can also be used as feed or fertilizer, and the market price of dry products is also between 300-350 yuan/ton. At present, various types of alcoholic beverages in China produce tens of millions of tons of synthetic alcohol annually. If calculated based on the yield of distiller's grains being 0.65 times that of alcohol, the quantity is considerable. If it is dried in a timely manner, it will be a considerable asset. But if left untreated or mishandled, alcohol lees will ferment and deteriorate in a short period of time, causing serious environmental pollution. The HYG series of multi ring drum drying equipment for waste residue has successfully solved this problem by drying the waste residue and turning it into a treasure.

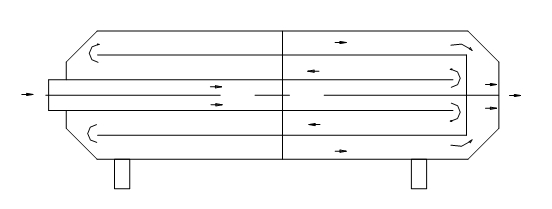

Structural features: Three sets of drums with different diameters form a multi ring drum. The inner and outer surfaces of the inner and middle ring drums are equipped with a reading board, and the inner surface of the outer ring drum is equipped with a reading board. The three-layer drum rotates at the same speed, and the material direction is: wet material enters the inner drum, returns from the end, enters the middle drum, goes to the first end, then enters the outer drum, and finally discharges from the end of the outer drum.

Suitable materials: drying various types of residue materials such as corn alcohol residue, cassava alcohol residue, Jerusalem artichoke meal, orange residue, apple residue, etc.

Performance characteristics:

1. Fast drying speed and high yield

Adopting a new high-temperature fast drying process, the entire line is automatically controlled, fed, coal fed, and slag discharged.

2. Good quality of dry items

The moisture content of alcohol residue is uniform, and high-temperature flue gas is used as the drying medium. The dried product meets national standards.

3. Production safety

This machine is equipped with a water spraying device and an explosion-proof device.

4. Low drying cost and multiple energy sources

Generally, high-efficiency and energy-saving coal-fired (or biomass particle) hot air furnaces are used, with a thermal efficiency 10 percentage points higher than ordinary dryers. Fuel such as oil and natural gas can also be used.

5. Can be used for multiple purposes in one machine

Can dry various sheet, fibrous, and granular materials.

For example: sawdust, grain residue, Ageratina adenophora, Broccoli stems and leaves, mulberry leaves twigs, ginger leaves, jerusalem artichoke meal, barley seedlings, Tagetes erecta, alfalfa grass, ginkgo leaves, corn germ, straw, Chinese herbal medicine, etc.

On site photos:

Process Flow Diagram

Process flow description:

The wet material is pushed into the feeding scraper conveyor, and the material layer is leveled by the leveling machine before the discharge port of the scraper conveyor. The material of equal thickness enters the feeding screw conveyor, and then is discharged into the outlet of the hot air stove. The high-temperature hot air generated by the coal-fired hot air stove is sucked into the three ring drum dryer for drying. The dried materials are sucked into the discharge system, and the mixed stones and other debris are deposited into the sedimentation device (regularly discharged). The dry materials are separated from the air in the collector, and discharged into the cooling system through a closed air discharge device. The cooled dry materials are discharged through a cyclone discharge device. Enter the packaging machine, bag and transport. A portion of the hot air discharged from the collector is discharged into the atmosphere, and most of it returns to the mixing chamber for heating. All units are controlled by the main control center, and the system is automatically controlled by a self-developed automatic control system.

The Hydronics can use electricity, oil, gas and coal, which are selected by the user.

Equipment Performance Table: