Product Introduction: The YXSG series rotary flash dryer is a new type of drying device developed and developed by our company. It combines the advantages of airflow drying, stirring drying, and fluidization drying, allowing the drying process to effectively control the degree of drying and material particle size. It is particularly suitable for high viscosity materials, heat sensitive materials, and can directly dry high viscosity materials into powder products. It is a chemical, pharmaceutical, ceramic Ideal drying equipment for the food industry.

Applicable materials: This dryer is mainly used for drying paste like materials, dregs, filter cakes, and wet crystalline materials in industries such as chemical, light industry, dyeing and chemical, pharmaceutical, etc.

Performance characteristics:

1. The equipment has high technical content and organically combines swirl, fluidization, spouting, and crushing classification technologies.

2. Large production capacity and high drying intensity. Due to centrifugation, shearing, collision, and friction, the material is highly dispersed and the relative velocity between the gas and solid phases is relatively high, which enhances mass and heat transfer and achieves efficient, fast, small equipment, and large-scale production.

3. No wall sticking or coking discoloration phenomenon. The dry gas enters the bottom of the dryer and generates a strong rotating airflow, which strongly washes out the materials on the wall and eliminates the phenomenon of wall sticking. In the high-temperature zone at the bottom of the dryer, heat sensitive materials do not come into direct contact with the hot surface. And equipped with special devices, it solves the problem of coking discoloration of heat sensitive materials.

4. The heat and mass transfer time during the drying process is short. Due to the high circumferential wind speed in the drying room, the material residence time is short, the heat loss is low, and the thermal efficiency is over 70%.

5. Effectively control the final moisture and particle size of materials. Effective control of final water content and finished product fineness is achieved through the installation of built-in materials (cyclone blades, ceramic ring or classifier) in the drying tower, and coordinated with the inlet and outlet air temperature.

6. It can handle paste like and filter cakes, as well as heat-sensitive materials. Compared with spray drying, the material does not need to be diluted, so the water evaporation is reduced, and the energy saving effect is remarkable.

On site photos:

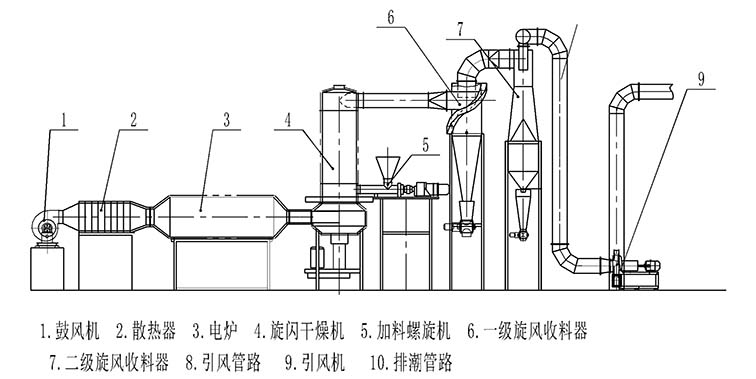

Process flow:

Process flow description:

The material enters the hopper and is fed into the screw conveyor. The screw conveyor continuously adds materials to the drying chamber, where the product comes into full contact with hot air. Hot air is blown into the drying chamber along a tangent direction by an air distributor at the bottom of the drying chamber. Clean air is heated by a heat exchange hot air furnace to reach the temperature required for drying. When the wet materials enter the drying chamber, they are scattered by the high-speed rotating blades in the drying chamber. Under the stirring of the blades, a stable and uniform material layer is formed at the bottom, and strong heat exchange is carried out with the Jet stream hot air coming from the bottom to quickly remove the moisture on the surface of the materials. The dried materials rise along the cylinder wall with the rising airflow, and large particles and partially dried powder are blocked by the grading ring, The bottom of the re dryer is crushed and dried, and the dry materials leave the drying chamber together with the wind and are transported to the primary Cyclonic separation separation system. In the Cyclonic separation system, the material powder is separated from the air, most of the materials are discharged from the rotary valve below, and some fine dust is sent to the secondary bag separation system by the tail wind for material air separation again. The exhaust gas from the secondary separator is uniformly recycled and treated in the factory. During the entire drying process, fully automatic control is used to control the yield and final moisture content of the product. We will control the outlet temperature of the dryer to control the moisture content of the product. When the exhaust temperature changes, adjust the inlet temperature to ensure the final moisture content of the product. This system maintains negative pressure operation throughout the entire process.

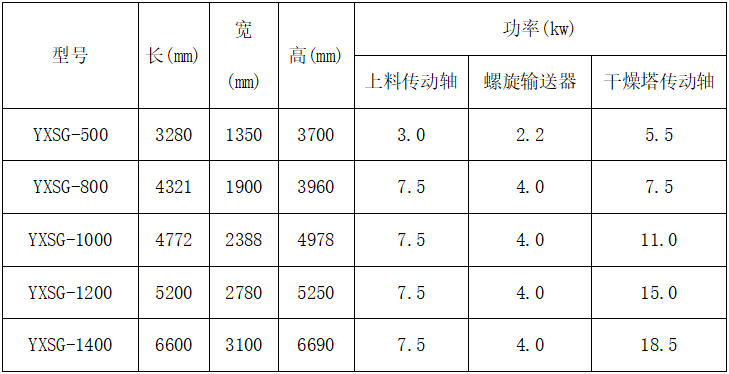

Performance Table: