Product introduction: HYG series multi ring drum drying complete equipment produced by our company was first used in Tagetes erecta drying industry in 2003. It has been more than 20 years now, with hundreds of sales at home and abroad. It is the largest manufacturer of Tagetes erecta drying equipment in China, with an outer diameter of more than 3.8 meters. All technical indicators have reached international standards. Its technology is mature, product quality is good, equipment operation time is long, and failure rate is low.

Applicable materials: Tagetes erecta, alfalfa grass, ginkgo leaves, sawdust, lees, alcohol lees, Ageratina adenophora, Broccoli stems and leaves, mulberry leaf twigs, ginger leaves, jerusalem artichoke meal, barley seedlings, corn germ, Chinese herbal medicine, etc.

Performance characteristics:

1. Advanced drying technology: Adopting a new high-temperature and rapid drying process, the three ring drum is equipped with a new structure, which has high drying strength and short material retention time in the dryer, greatly increasing the output compared to dryers of the same volume.

2. High degree of automation: using a fuzzy control system for letters to achieve automatic control of product quality.

3. Production safety: Equipped with automatic fire and explosion-proof devices to ensure safe operation.

4. Low drying cost: Adopting an efficient and energy-saving coal-fired hot air stove, a new high-temperature and rapid drying process, and a three ring drum set structure, the comprehensive thermal efficiency is increased by 15-18 percentage points, greatly reducing the drying cost.

5. The quality of dry products is good: the moisture content of dry materials is balanced, the amount of nutrients is high, the color is bright, and the loss of Lutein is very small.

6. The one-time investment is 25-30% less than that of a neat dryer; Drying costs are 20-25% less than steam dryers

7. Multi purpose machine: capable of drying various sheet, fibrous, and granular materials.

Drying effect: too long drying time of Tagetes erecta and uneven heating in the drying process are two major problems affecting the drying and processing quality of Tagetes erecta. The complete drying equipment for Tagetes erecta developed and produced by our company has successfully solved the above two problems. The following figure shows the Tagetes erecta granule effect after drying with our HYG series multi ring drum drying complete equipment. It can be seen that the dried product is golden in color and of good quality.

On site photos:

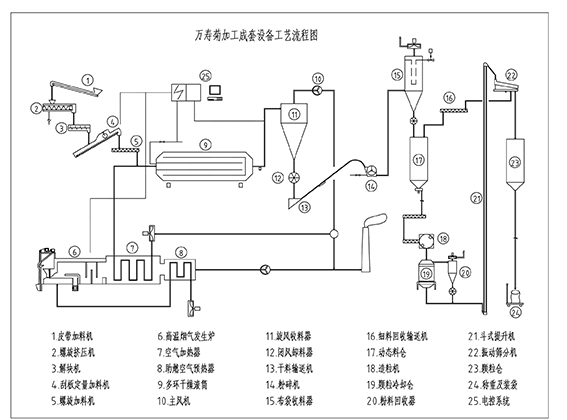

Process flow diagram:

Process flow description: The fermented chrysanthemums are added to the anti clogging feeding bin by a forklift, and the material is uniformly fed (variable frequency speed regulation) to two extruder feeding jacks by a screw inside the bin. The feeding jacks are then fed to the screw extruder, and the dehydrated material is collected by the aggregate jacks and sent to the breaking machine for dispersion before entering the scraper conveyor. The scraper conveyor is then fed to the feeding shut-off fan, which is then fed to the feeding inlet of the dryer through the feeding shut-off fan, At the feeding port, the material comes into full contact with the hot flue gas from the hot air stove. Under the action of the induced draft fan, it carries the same material into the drying host and undergoes three rounds of mass and heat exchange to complete the drying of the material. The dried material enters the cyclone collector and undergoes material air separation in the collector. The dry material enters the crushing and granulation process through the discharge air shutter, and the moisture from the cyclone is discharged into the atmosphere through the main induced draft fan and the exhaust chimney. The dried material directly enters the subsequent crushing and granulation section, where it is crushed, granulated, and cooled to complete the entire production process.

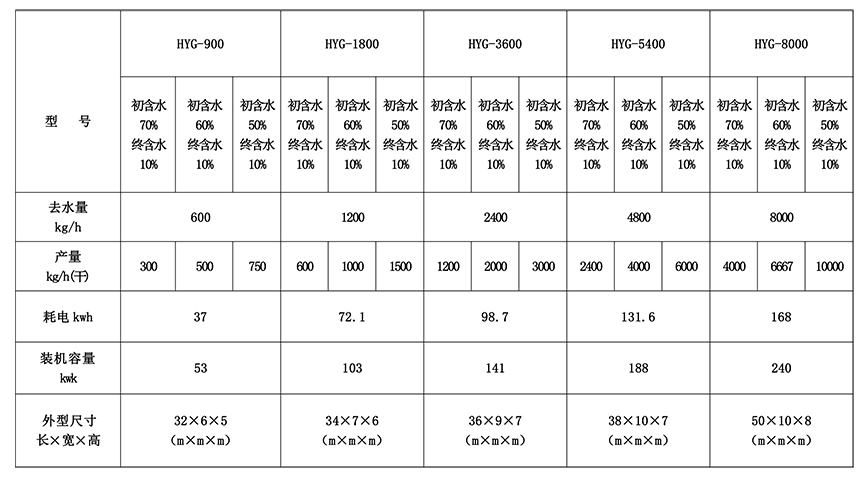

Equipment Performance Table: