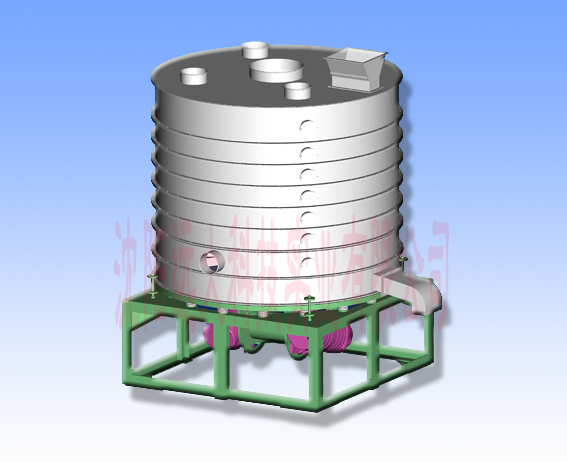

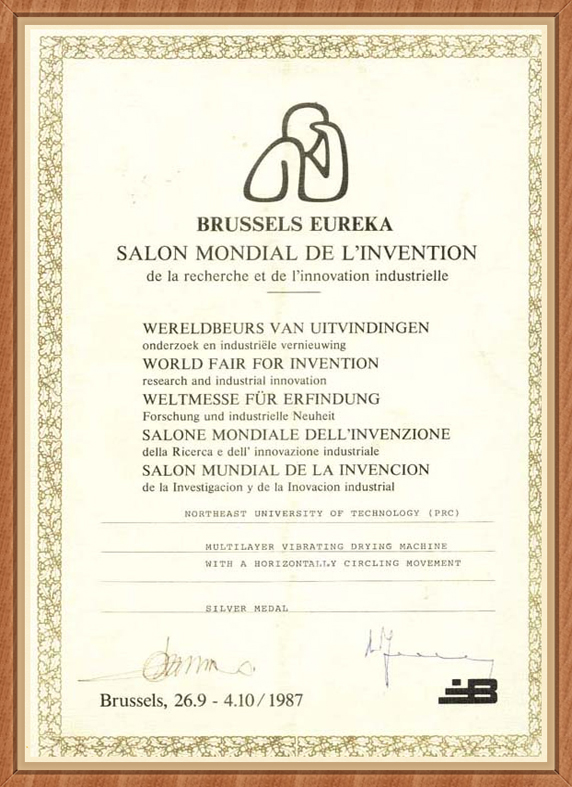

Product Introduction: The vibrating multi-layer horizontal circular dryer was developed under the leadership of Professor Lu Yinglin, a renowned drying technology expert in China. In 1987, it won a silver medal at the 36th Brussels International Invention Conference and also won the second prize of the National Science and Technology Progress Award.

Applicable materials:

Suitable for drying and cooling powdered materials in industries such as food, chemical, pharmaceutical, feed, bait, plastic, salt making, grain, seed, tobacco, sugar, metallurgy, etc., such as organic pharmaceutical powder, salt, seasoning, additives, monosodium glutamate, shrimp bait, etc.

Performance characteristics:

1. Energy saving. Due to the fact that the material is in direct contact with the hot air, it saves 30% of thermal energy and 40% of electrical energy compared to the same type of dryer.

2. High drying quality and good effect. The material jumps and moves along the horizontal annular orifice plate, so there is no local overheating and uneven drying phenomenon that commonly exists in dryers. The material has low crushing rate, less wear, and the moisture content of the finished product is less than 0.1%.

3. Investment Province. Due to the use of multi-layer stacking, the material moves vertically at one end, resulting in a compact structure, occupying one-fifth of the same type of dryer area, and being sturdy and durable, with reliable sealing, convenient maintenance, and light weight.

4. Widely used. The material movement state and flow rate can be adjusted steplessly, so it is suitable for powder and granular materials with a moisture content of less than 40% and a permissible temperature of less than 400 ℃.

5. Low noise, good vibration isolation performance. It can be floating on the floor for easy operation, installation, and relocation, and has a good working environment.

6. High production efficiency. When the material is in motion, it comes into full contact with hot air multiple times, resulting in high thermal efficiency. Therefore, the unit hourly output is 2.2-3 times that of the same type of dryer.

7. It can be equipped with an automatic feeding device (patented) for uniform feeding, forming an automatic flow production line.

On site photos:

Process flow:

Process flow description: The two vibration motors installed in the lower part of the main machine synchronously rotate in reverse, causing vertical and torsional vibrations to occur in the main machine body composed of multi-layer annular holes installed on the stage. The material entering from the feeding port is continuously jumping and moving along the horizontal annular hole plate from the upper layer to the lower layer from the page; The hot air flows from the lower layer to the upper layer through each layer of orifice plates and passes through the material layer, achieving the goal of uniform drying of the material.

Performance Table: