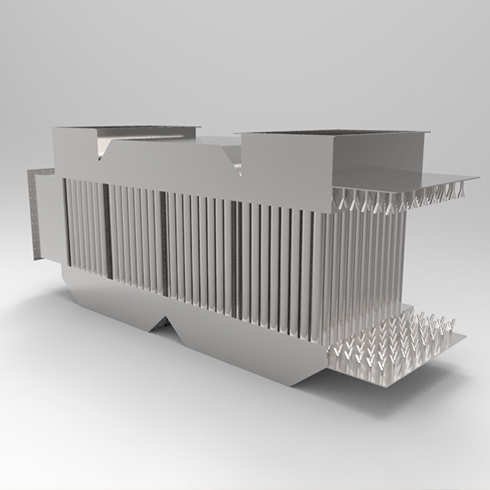

The HYG series multi ring drum complete set of large-scale drying equipment consists of six systems and 20 units, which adopt automatic control of fully enclosed operation: feeding system, hot air system, drying host, receiving system, and cooling system.

Due to the excitation force generated by the two vibration motors installed on the main body, the material jumps forward along the horizontal orifice plate; The hot air passes through the orifice plate from the bottom up and passes through the material layer to achieve the purpose of dehydration and drying.

The two vibration motors installed in the lower part of the main machine synchronously rotate in reverse direction, causing vertical and torsional vibrations to occur in the main body composed of multiple circular holes installed on the stage. From the page, the material entering from the feeding port continuously jumps and moves along the horizontal circular hole plate from the upper layer to the lower layer

The YXSG series rotary flash dryer is a new type of drying device developed by our company, which combines the advantages of airflow drying, stirring drying, and fluidized bed drying

A heat exchange hot air furnace is a type of hot air generator that uses coal or biomass fuel combustion to heat the air. It can provide clean, high-temperature air for the drying of food and medicine.

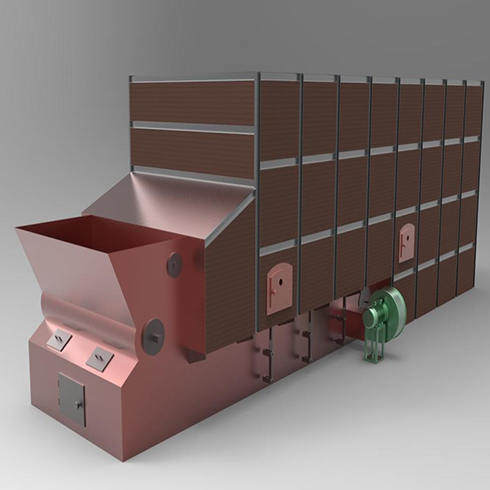

A hot flue gas furnace is a mechanical chain grate furnace that generates high-temperature flue gas. It is mainly used for drying and providing 200-1000 ℃ high-temperature purified flue gas. The furnace is equipped with energy-saving combustion arches and high-temperature purification rooms, with a thermal efficiency of over 90%. The fuel is coal or biomass fuel.

Highly automated, with more complete combustion, it can provide stable energy supply for boilers or drying.

Oil and gas hot blast stove is a hot flue gas generator that uses oil or gas as fuel. The high-temperature flue gas generated by the combustion of oil or gas provides the required high-temperature flue gas for drying or other heating equipment.

Used for dehydration of various fiber materials, it can remove most of the moisture in the material.

Utilize some of its own products as fuel without the need for additional fuel addition

Utilize some of its own products as fuel without the need for additional fuel addition

Equipped with a dedicated sawdust cyclone burner and automatic return system

Equipped with a dedicated sawdust cyclone burner and automatic return system

Equipped with a dedicated sawdust cyclone burner and automatic return system

Equipped with a dedicated sawdust cyclone burner and automatic return system

Equipped with a dedicated sawdust cyclone burner and automatic return system

Equipped with a dedicated sawdust cyclone burner and automatic return system

Shenyang Yuanda Technology Industry Co., Ltd. was founded in 1997 and is headquartered in Huishan Development Zone, Shenyang. It covers an area of 10000 square meters and has a research institution - Shenyang Dongda

Drying Technology Research Institute, a manufacturing plant - Liaoning Yuanda Drying Technology Co., Ltd. (located in Tieling High tech Zone). The chairman and general manager of the company, Lu Yinglin, is a senior professor and professor at Northeastern University

Former Director of the Drying Research Institute, Chairman of the Liaoning Drying Technology Society, and a nationally recognized drying technology expert with outstanding contributions.

Sales hotline

Sales hotline

Address: 33A, Tongshun Street, Shenbei New Area, Shenyang, Liaoning

Email hosting service: yd@syydgz.com